Mill coolant system design

Flushing by Design

Much like a river carries solids and liquids, a coolant system in roll forming and tubemaking moves contaminants from the point of entrance to a point of removal. Hoses spray coolants like rain over tools and profiles to keep them clean and remove heat generated in the process. And just like rain into a river, if coolant is deposited directly, the resulting current then can carry contaminants away.

Coolant systems work in a closed loop, so contaminants must be removed using strainers, filters, skimmers, and other mechanical methods. If they are not removed, contaminants build up quickly and can have deleterious effects on profile production, storage, fabrication, and finishing processes.

Plumbing, Reservoirs, and Pumps

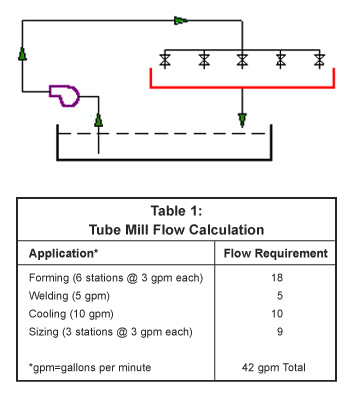

Figure 1:

Simple coolant system schematic